Decorators

Up to 8 Colours for beautiful designs

Up to 2,400 cans per minute

All Can sizes up to 250mm print height

Quick label changeover time

Rapid can-size change system the fastest in the industry

Outstanding print quality

Very reliable and economic to operate & maintain

Suitable for aerosol, bottles and other containers

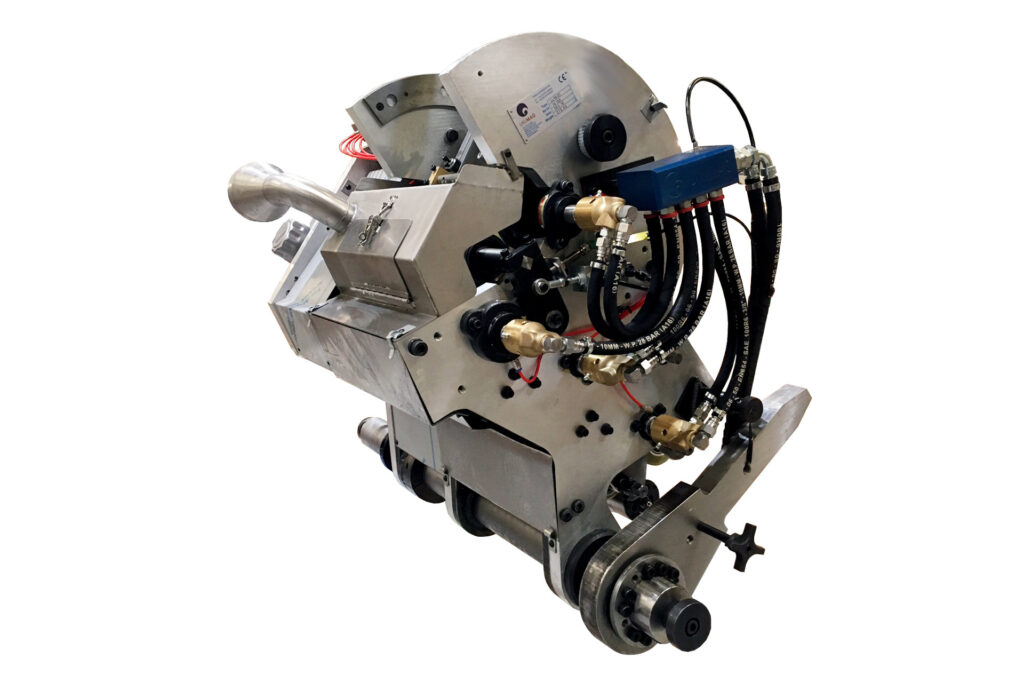

Inkers

Quick label change

Electronic Ductor Roller control

Individual temperature control

Premium Rollers provide extended life and optimum performance

Automatic lubrication system

Inker Wash up kit and Fountain Agitator

Ultra-Violet Bottom Rim Coaters

Increased can mobility and better can rim protection

Coating cured by UV light instead of thermal ovens

Increases line efficiency and reduces spoilage

Easier to control film thickness and application

Both can dome-up and can dome-down configurations available

Elimination of VOC emissions

Safest system in the industry Zero Accidents

All can sizes

Range of conveyor widths and speeds

Automatic system, no requirement for an operator

Fully integrated

Low maintenance

LED Ultra-Violet Bottom Rim Coaters

Reduction in harmful greenhouse gases including CO2 and Ozone

Short investment payback period typically 9 to 18 months

Much reduced fire risks

Reduced continual running costs, no need for intake or exhaust fans or ducting

Reduced spares and maintenance, Lamp 30,000 Hour Lifetime (3.4 yrs.)

No Mercury

No Microwave exposure

Over Varnish Units

Reduced varnish misting

Flat-belt pre-spin

Quick-change gravure and applicator rollers

Special applications: Tactile, Thermochromic, Fluorescent and more

Modular design for easy maintenance

Graduated, laser-engraved gravure roller

Mechanical or electronic drive

Basecoater

Single servo-driven coating head

Up to 1,800 cans per minute

Independent motor-driven pre-spin

Leading white-coat application

Pressurised supply pump and filter arrangement

Rapid can-size change system the fastest in the industry